In the realm of modern manufacturing, the Gantry Machining Center (GMC) stands out as a cornerstone of precision, efficiency, and versatility. This advanced machining tool has revolutionized the way industries approach large-scale production, enabling the creation of complex components with unparalleled accuracy. From aerospace to automotive industries, the Gantry Machining Center has become an indispensable asset, driving innovation and productivity.

What is a Gantry Machining Center?

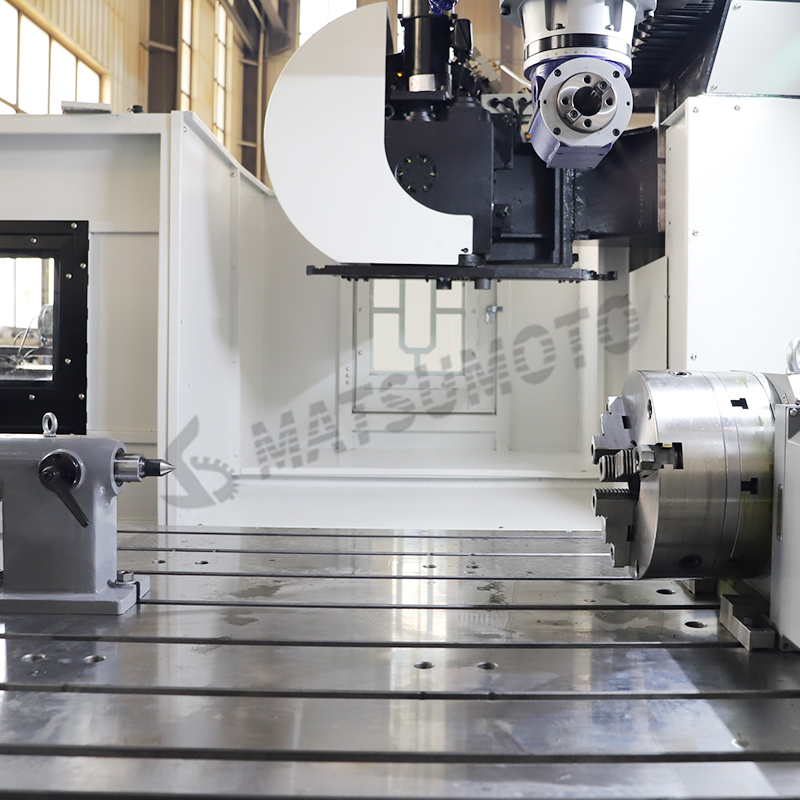

A Gantry Machining Center is a type of CNC (Computer Numerical Control) machine that features a bridge-like structure, or gantry, which spans the workpiece. Unlike traditional machining centers, where the workpiece is typically fixed and the cutting tools move, in a GMC, the gantry moves along the X, Y, and Z axes, allowing for greater flexibility and precision when handling large or heavy materials.

The gantry design provides exceptional stability and rigidity, which is crucial for maintaining accuracy during high-speed machining operations. This makes Gantry Machining Centers particularly well-suited for tasks that require intricate detailing and tight tolerances, such as the production of molds, dies, and large structural components.

Key Features and Advantages

1. Large Work Envelope: One of the most significant advantages of a Gantry Machining Center is its ability to accommodate large workpieces. The open design of the gantry allows for the machining of parts that would be impossible to handle on conventional vertical or horizontal machining centers.

2. High Precision and Stability: The rigid structure of the gantry minimizes vibrations and deflections during machining, ensuring consistent accuracy even at high speeds. This is particularly important for industries where precision is paramount, such as aerospace and defense.

3. Versatility: Gantry Machining Centers are capable of performing a wide range of operations, including milling, drilling, tapping, and boring. This versatility makes them ideal for producing complex parts with multiple features in a single setup.

4. Automation and Integration: Many Gantry Machining Centers are equipped with advanced automation features, such as automatic tool changers, pallet changers, and robotic loading systems. These features enhance productivity by reducing downtime and enabling continuous operation.

5. Scalability: Gantry Machining Centers can be customized to meet specific production needs. Whether it's increasing the size of the work envelope or adding specialized tooling, these machines can be tailored to suit a variety of applications.

Applications Across Industries

The versatility and precision of Gantry Machining Centers have made them a popular choice across a wide range of industries:

- Aerospace: In the aerospace industry, where components must meet stringent quality standards, Gantry Machining Centers are used to produce large structural parts, engine components, and intricate molds with high precision.

- Automotive: The automotive industry relies on Gantry Machining Centers for the production of large dies, molds, and prototypes. The ability to machine complex geometries with tight tolerances is essential for developing high-performance vehicles.

- Energy: In the energy sector, Gantry Machining Centers are used to manufacture components for wind turbines, hydroelectric plants, and oil and gas equipment. The machines' ability to handle large, heavy parts is particularly valuable in this industry.

- Heavy Machinery: Industries that produce heavy machinery, such as construction equipment and agricultural machinery, benefit from the Gantry Machining Center's ability to machine large, robust components with precision.

Future Trends and Innovations

As manufacturing technology continues to evolve, Gantry Machining Centers are expected to become even more advanced. Innovations such as artificial intelligence (AI) and machine learning are being integrated into CNC systems, enabling predictive maintenance, real-time monitoring, and adaptive machining. Additionally, the development of hybrid machines that combine additive and subtractive manufacturing processes is opening up new possibilities for producing complex, high-performance components.

Sustainability is also becoming a key focus in the design of Gantry Machining Centers. Manufacturers are increasingly adopting energy-efficient technologies and materials to reduce the environmental impact of machining operations.

Conclusion

The Gantry Machining Center represents a significant leap forward in manufacturing technology, offering unmatched precision, versatility, and efficiency. As industries continue to demand higher levels of performance and complexity in their Products, the role of Gantry Machining Centers will only grow in importance. By embracing the latest advancements in CNC technology, manufacturers can stay ahead of the curve and continue to push the boundaries of what is possible in precision engineering.

In a world where innovation is the key to success, the Gantry Machining Center stands as a testament to the power of technology to transform industries and drive progress.

Hot News

Hot News2025-01-04

2024-12-20

2024-08-19

2024-10-28

2024-09-11

2025-01-30