GMB1713 Gantry Machining Center

- Overview

- Related Products

- Product Parameters:

- Application:

- Details Images

- Packaging & Shipping

- Company Profile

- Certification:

- FAQ:

All machines in our company have multiple colors to choose from, and we support customers to customize exclusive colors!

This machine is used in CNC milling, boring, drilling, tapping, processing of steel, cast steel, cast iron etc.. Machine tool accessory head to realize the of all kinds of plate, plate, shell and mould for complex parts in a fixture in complete drilling,milling, boring, reaming, reaming, tapping a variety of processes. It can be used for small batch spare parts, processing and manufacturing, of complex, high precision parts processing more show its superiority, also can compose the automatic production line for mass production, to ensure the parts of product quality and efficient production.

Suitable for rough and precision machining of automotive components auch as wheel hubs and discs. The machine tool adopts a roller type linear slide rail. Has ultra-high rigidity and overload capacity.

MODEL |

UNIT |

GMB1713 |

||

|

Worktable |

Table size |

mm |

1200*1600 |

|

Distance between two vertical columns |

mm |

1300 |

||

Max. Table load |

kg |

5000 |

||

T-slotted size |

mm |

22*7 |

||

|

Processing range |

Max. Travel of workbench-X axis |

mm |

1700 |

|

Max. Travel of sliding saddle-Y axis |

mm |

1300 |

||

Max. Spindle travel-Z axis |

mm |

800 |

||

Distance from spindle end face to worktable |

Max |

mm |

950 |

|

Min |

mm |

150 |

||

|

Spindle |

Bore-hole(7:24) |

/ |

BT40-Φ150 |

|

Revolution range |

r/min |

40-8000 |

||

Main motor model |

N.m |

D15 |

||

Max. Power of motor |

kw |

15 |

||

|

Four-axis |

Model |

/ |

B320 |

|

Dimension of worktable |

mm |

320 |

||

Center height |

mm |

210 |

||

Reduction ratio |

/ |

1:60 |

||

Motor torque |

Nm |

12 |

||

Segmentation accuracy |

" |

±15 |

||

Repeat positioning accuracy |

" |

6 |

||

Bearing |

Vertical |

kg |

180 |

|

Horizontal |

kg |

350 |

||

|

Tool magazine |

Capacity |

T |

24 |

|

Max. Tool weight |

kg |

8 |

||

Max. Tool diameter(full blade) |

mm |

Φ78 |

||

Max. Tool diameter(free face blade) |

mm |

Φ112 |

||

Max. Tool length |

mm |

300 |

||

Tool change time |

s |

2.5 |

||

|

Feed |

Range of cutting feed rate |

mm/min |

1-10000 |

|

|

Fast moving |

X axis |

m/min |

20 |

|

Y axis |

m/min |

20 |

||

Z axis |

m/min |

16 |

||

|

Feed motor |

X axis |

KW/NM |

3/22 |

|

Y axis |

KW/NM |

3/22 |

||

Z axis |

KW/NM |

3/22 |

||

|

Three-axis screw |

X axis |

mm |

Φ50-12 |

|

Y axis |

mm |

Φ40-12 |

||

Z axis |

mm |

Φ40-12 |

||

|

Three-axis linear guide rail |

X axis |

mm |

2-45 |

|

Y axis |

mm |

2-45 |

||

Z axis |

mm |

4-45 |

||

|

Machine tool positioning accuracy |

X axis |

Execution standards: JB/T8771.4-1998 |

mm |

0.022 |

Y axis |

mm |

0.018 |

||

Z axis |

mm |

0.015 |

||

|

Repeat positioning accuracy |

X axis |

Execution standards: JB/T8771.4-1998 |

mm |

0.012 |

Y axis |

mm |

0.010 |

||

Z axis |

mm |

0.010 |

||

Wright |

kg |

9600 |

||

Total electrical capacity |

KVA |

48 |

||

Dimension(L*W*H) |

mm |

6130*2670*3280 |

||

|

THREE-AXIS LINEAR SLIDER RAIL

Three-axis linear slide rail, with high rigidity, high precision accuracy, low noise, low firction characterists.

|

|

MAIN STRUCTURE

Main structure castings adopt high quality Mihanna cast iron, stable structure, permanent ensure quality. |

|

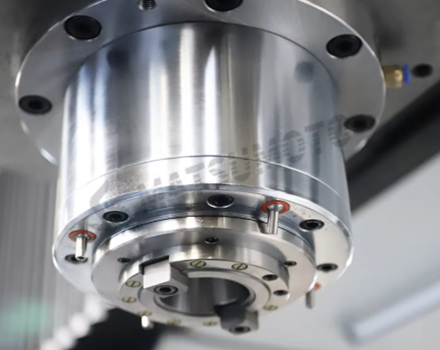

5TH AXIS CNC INDEXING PLATE

After installing the 5th axis CNC indexing plate, multiple processes can be assembled into one process, and it is accurate to one thousandth of a degree.

|

|

TOOL MAGAZINE

The tool magazine is equipped with an automatic tool changer ATC(Auto Tool Change) for automatic tool exchange.

|

|

CNC SYSTEM

CNC control system can be choosed, like KND/GSK/SIEMENS/FANUC/MITSUBISHI and other good system.

|

1.Standard plywood case,its compressive strength and bearing quality is better.

2.The board area is bit,the soil structure is good,it is better in leak proofness and waterproof.

3.When importing,the plywood case is with fumigation-free,the procedure is simple.

4.Delivery Detail:within 7-15 days after received your payment.

Shandong Matsumoto Machine Tool Co., Ltd.specializes in the production of processing machine tools. Its main Products include precision products such as CNC lathes, surface grinders,milling machines, and vertical machining centers. It has a complete and scientific quality management system. Shandong Matsumoto Machine Tool Co., Ltd. operates with integrity, and its production strength and product quality have been recognized and praised by the industry.It is a comprehensive machine tool manufacturing enterprise integrating CNC machine tool manufacturing and consulting services. The company has a complete R&D and after-sales service team. Welcome to visit, guide and negotiate business with the company.

Main products:

CNC LATHE MACHINE、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine.

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine and so on .

3: What about the quality of the machine?and after-sales service?

A : Our machine warranty period is 3 years,and we provide free technical service.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment

before shipment ;

Irrevocable LC at sight .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )