ZX6350 Drilling and Milling Machine

- Overview

- Related Products

- Product Parameters:

- The main performance characteristics:

- Application:

- Details Images

- Packaging & Shipping

- Company Profile

- FAQ:

All machines in our company have multiple colors to choose from, and we support customers to customize exclusive colors!

Using rectangular guide machine is Rigid good.

Work table and guide rail through the ultra audio spark quenching.

Automatic feed in X-axis.

Milling head can be rotated 45 degrees.

DRO supplied at extra cost.

Universal milling and drilling machine is a kind of general metal cutting machine tool.

Spindle taper hole of the machine can be directly or through the attachment installed all cylindrical milling cutter, disc cutter,molding cutter, end milling cutter tool, suitable for processing a variety of small parts of plane, inclined plane, grooves,holes, and other gear. Is a mechanical manufacturing, mold, equipment, instruments, automobiles, motorcycles and other industries of the ideal processing equipment.

Smooth operation, wear-resistant and durable. The milling head has rotational speed, good accuracy, and meets the need of rough and precision machining.

PROJECT |

UNIT |

ZX6350 |

ZX6336 |

Max. Drilling diameter |

mm |

50 |

50 |

Max. Width of end milling |

mm |

100 |

100 |

Max. Vertical milling diameter |

mm |

25 |

25 |

Max. Boring diameter |

mm |

120 |

120 |

Max. Tapping diameter |

mm |

M16 |

M16 |

Distance from spindle to worktable |

mm |

80-460 |

100-480 |

Spindle speed range |

rpm |

115-1750(v) 40-1300(h) |

115-1750(v) 40-1300(h) |

Spindle travel |

mm |

120 |

120 |

Table size |

mm |

1200*280 |

1500*320 |

Worktable travel |

mm |

600/300/300 |

850*320*400 |

Motor power |

kw |

1.5/2.2(v) 2.2(h) |

2.2(v/h) |

Wright |

kg |

1400 |

1950 |

Dimension(L*W*H) |

mm |

1400*1290*2250 |

1710*1720*2330 |

|

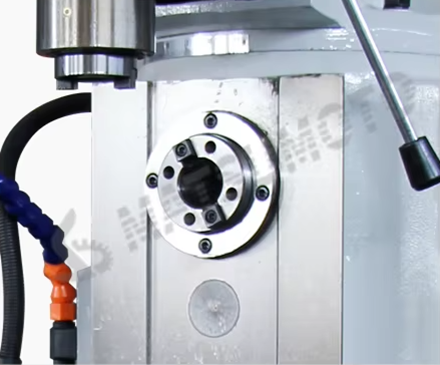

Z TYPE TURRET HEAD

Gear drive Z head, high cutting force, fixed-rang cutting, fast and convenient. |

|

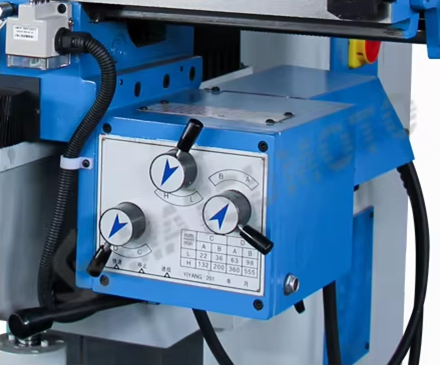

CONTROL PANEL

Centralized control panel, easy to operate, fast and safe. |

|

X/Y/Z AUTO FEED

X/Y axis auto feed, Z axis electric lifting, improve processing time. |

|

VERTICAL&HORIZONTAL

Vertical and horizontal mill, high speed, high quality, widely processing range. |

|

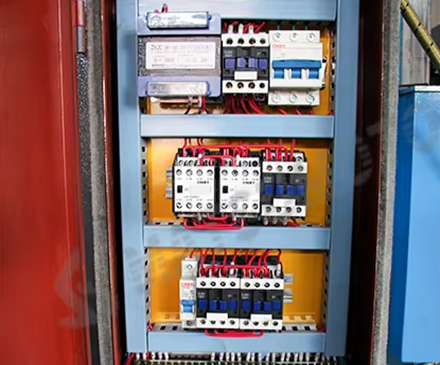

NEAT CIRCUIT

The electric box is neat and clean, and the maintenance links are clear at a glance. |

|

CASTING

It is cast with high quality materials and is tempered twice to improve the precision retention of the castings. |

|

3 AXIS DRO

3 axis digital readout is optional, need extra cost.(optional) |

1.Standard plywood case,its compressive strength and bearing quality is better.

2.The board area is bit,the soil structure is good,it is better in leak proofness and waterproof.

3.When importing,the plywood case is with fumigation-free,the procedure is simple.

4.Delivery Detail:within 7-15 days after received your payment.

Shandong Matsumoto Machine Tool Co., Ltd.specializes in the production of processing machine tools. Its main products include precision products such as CNC lathes, surface grinders,milling machines, and vertical machining centers. It has a complete and scientific quality management system. Shandong Matsumoto Machine Tool Co., Ltd. operates with integrity, and its production strength and product quality have been recognized and praised by the industry.It is a comprehensive machine tool manufacturing enterprise integrating CNC machine tool manufacturing and consulting services. The company has a complete R&D and after-sales service team. Welcome to visit, guide and negotiate business with the company.

Main products:

CNC Lathe Machine、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine.

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine and so on .

3: What about the quality of the machine?and after-sales service?

A : Our machine warranty period is 3 years,and we provide free technical service.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )