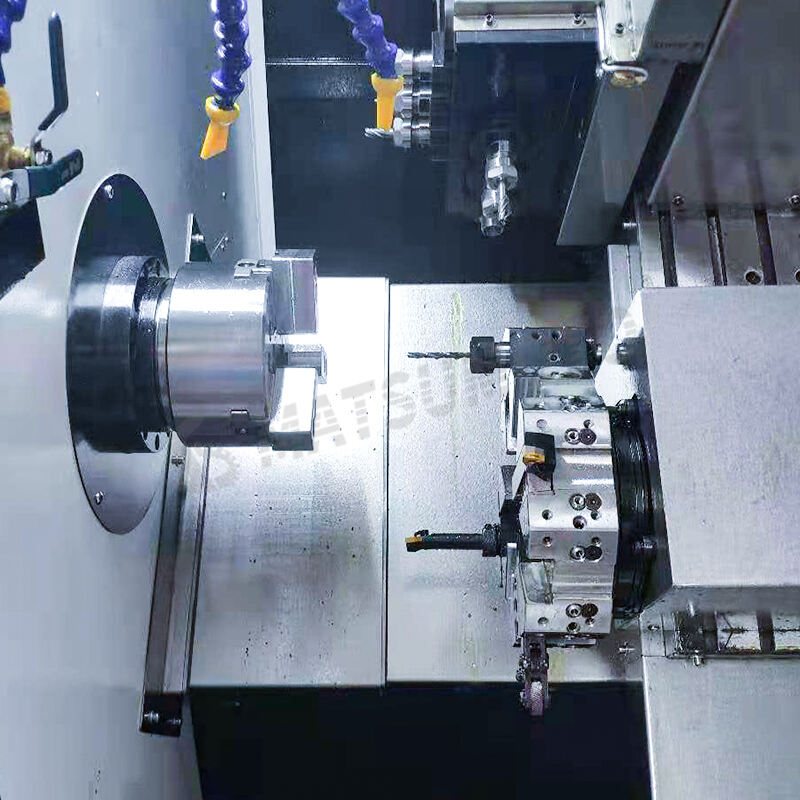

turning centre in cnc

The turning centre in CNC machining is a sophisticated piece of equipment designed for high precision metal cutting operations. Its main functions include rotating a workpiece about its axis while a cutting tool removes material to achieve the desired shape and finish. Technological features of the turning centre include a powerful spindle drive, automatic tool changers, and advanced control systems that allow for complex operations with ease. These machines are versatile, capable of performing a variety of tasks such as facing, turning, boring, and threading. Applications span across numerous industries, from automotive and aerospace to medical devices and energy, where precision and efficiency are paramount.