gantry type vertical machining center

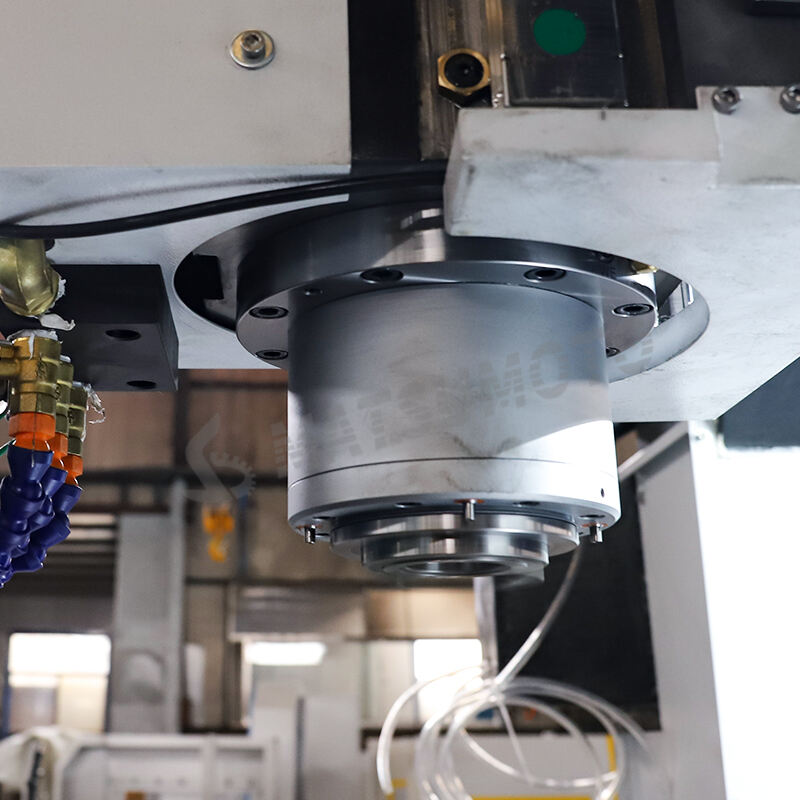

The gantry type vertical machining center is a precision engineering marvel designed for versatility and efficiency in modern manufacturing. It operates with a vertical spindle orientation and features a gantry-style framework that provides exceptional stability and rigidity. The main functions include milling, drilling, tapping, and contouring operations, all performed with high accuracy on a variety of materials. Technological features such as direct linear drives, high-speed spindles, and advanced control systems enable precise and rapid machining. Its applications span across industries like automotive, aerospace, and general machinery manufacturing, where complex parts require high-quality finishing. With automated tool changers and CNC capabilities, this machining center streamlines production and enhances productivity.