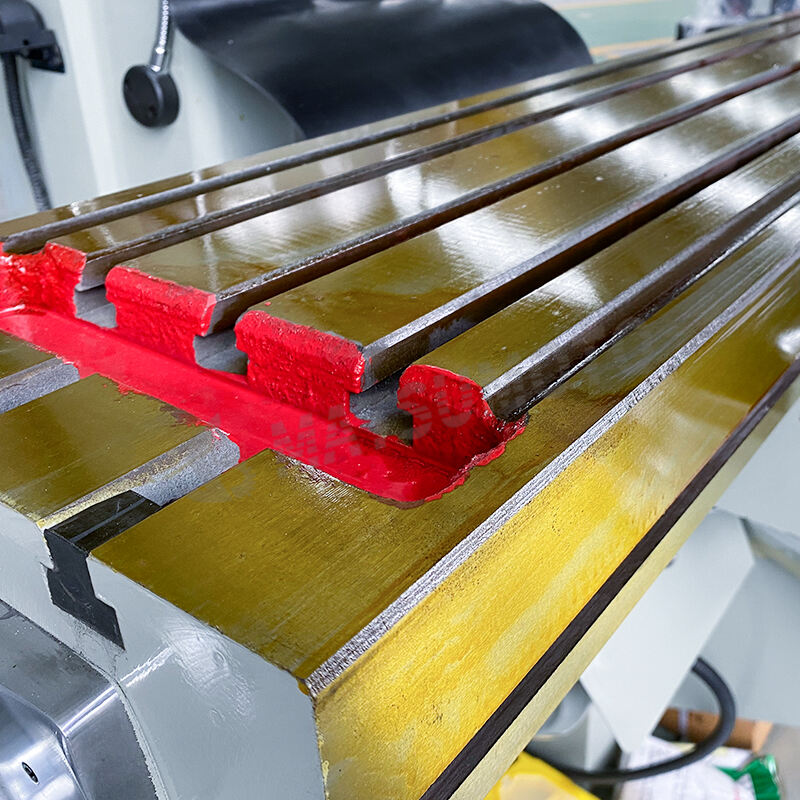

conventional vertical milling machine

The conventional vertical milling machine is a robust and versatile equipment used in various industries for the shaping and processing of metal and other solid materials. At its core, this machine performs three main functions: facing, drilling, and end milling. Technological features include a vertically oriented spindle that holds and rotates the cutting tool, while the workpiece is mounted on a moveable table. This configuration allows for precision cutting in multiple directions. The machine's applications are widespread, from manufacturing intricate parts for automobiles and aerospace to creating detailed molds for the plastic and die-casting industries.