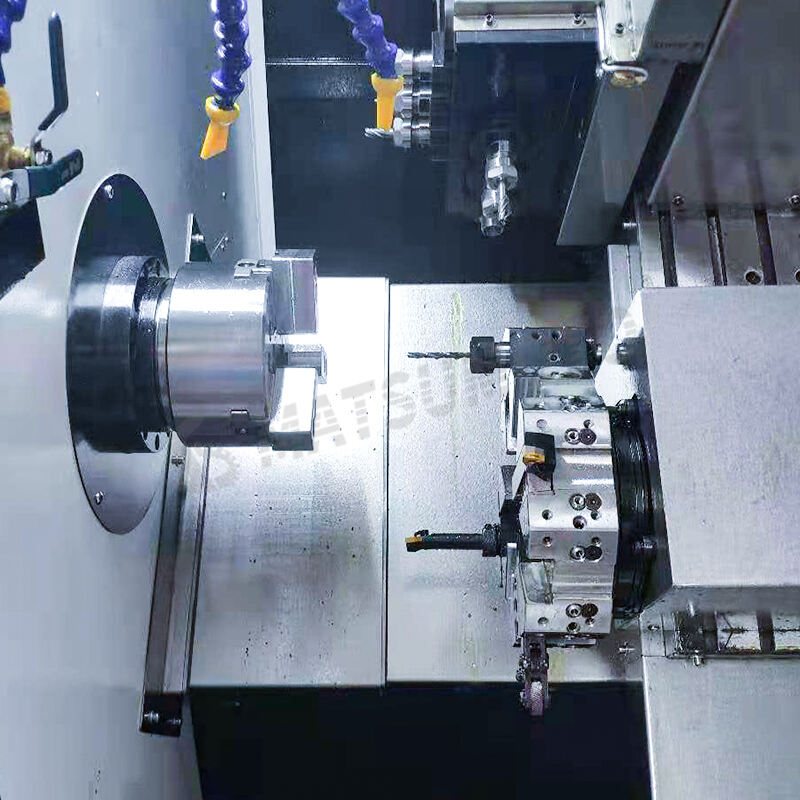

conventional lathe machine

The conventional lathe machine is a fundamental tool in the field of metalworking and manufacturing. Characterized by its sturdy design and manual operation, this machine is equipped with a rotating workpiece that's driven by an electric motor. Its main functions include cutting, facing, turning, sanding, and knurling operations. Technological features of the conventional lathe machine include a variable speed drive, a coolant system for reducing heat during operation, and a range of tool holders for various cutting tasks. These capabilities make it suitable for a wide array of applications such as machining parts with precise outer diameters and lengths, creating threads, and shaping metal components to exact specifications. Its versatility makes it an indispensable part of both small workshops and large-scale industrial settings.