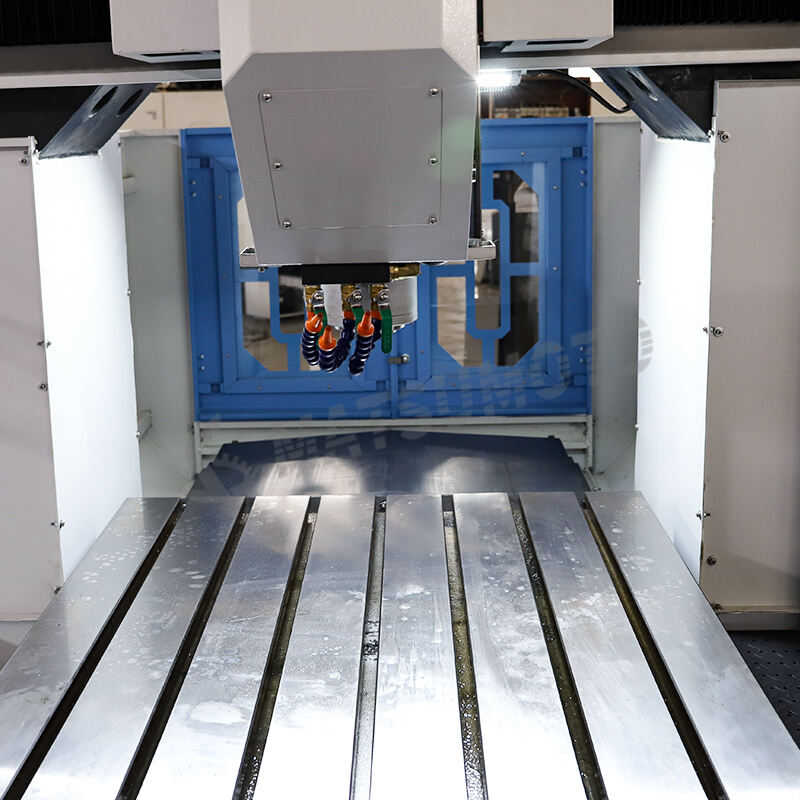

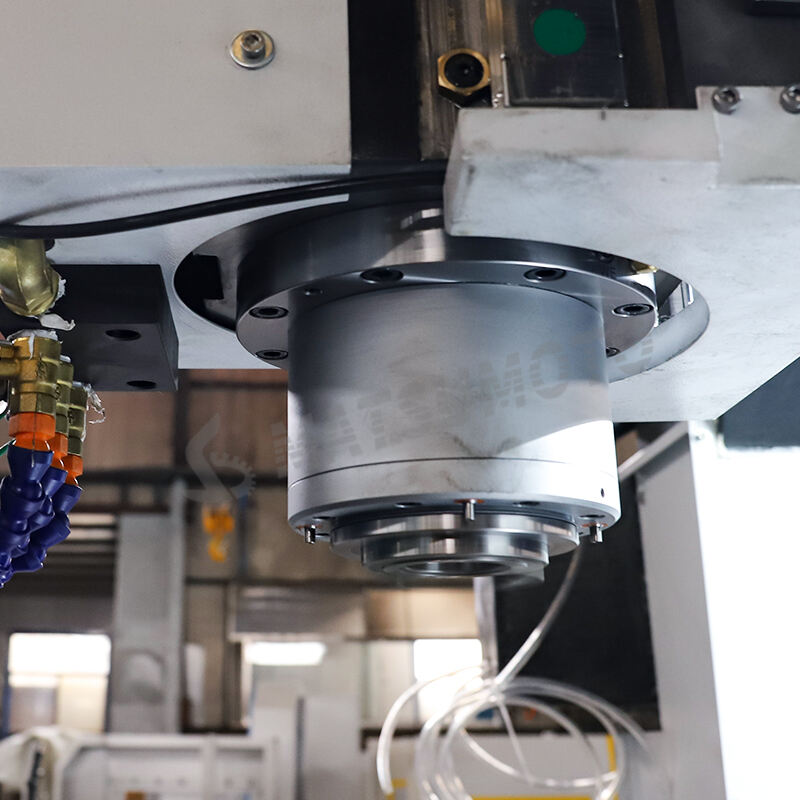

cnc gantry type machining center factory

The CNC gantry type machining center factory is a state-of-the-art facility designed to produce high precision parts and components. At the heart of this factory are the CNC gantry type machining centers, robust machines capable of performing a variety of functions such as milling, drilling, tapping, and boring. These machines boast advanced technological features like high-resolution digital readouts, automatic tool changers, and sophisticated control systems that ensure precision and efficiency. The applications of these machining centers are vast, from aerospace and automotive manufacturing to heavy machinery and energy sector components, making them indispensable in modern industry.