5 axis gantry type machining center

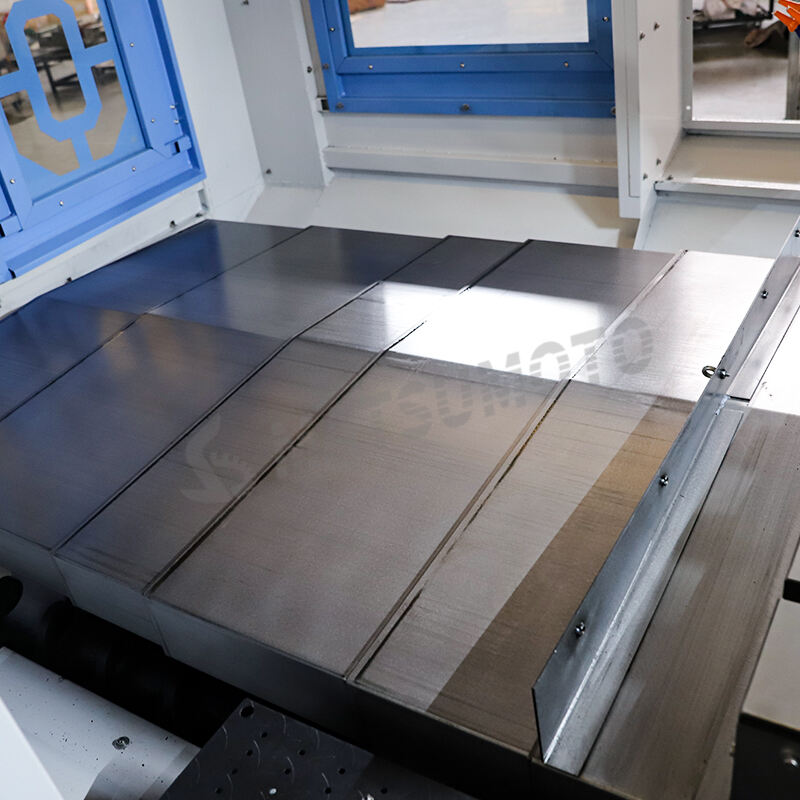

The 5 axis gantry type machining center is a state-of-the-art piece of equipment designed for high precision and complex machining tasks. It operates on five separate axes simultaneously, allowing for unparalleled flexibility and accuracy. The main functions include milling, drilling, and tapping operations, all performed with exceptional speed and precision. Technological features include a robust gantry structure for stability, direct linear drives for smooth and rapid movement, and advanced control systems for intricate part manufacturing. This machining center is ideal for applications in aerospace, automotive, and general engineering industries where intricate and large-scale components require precision machining.