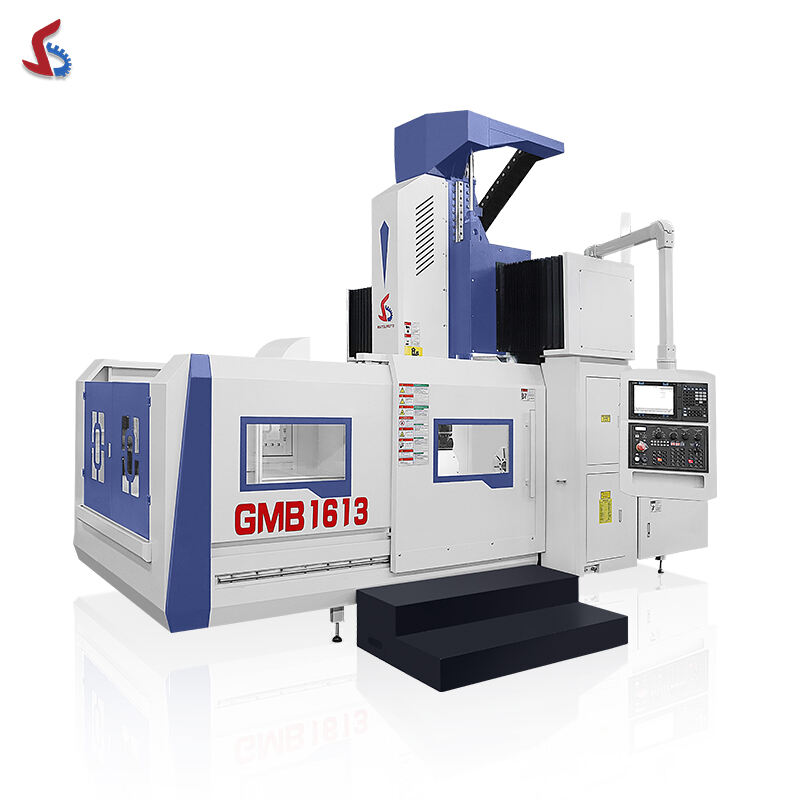

CNC Lathe Machine Slant Bed TCK56Y

- Overview

- Related Products

- Product Parameters:

- Application:

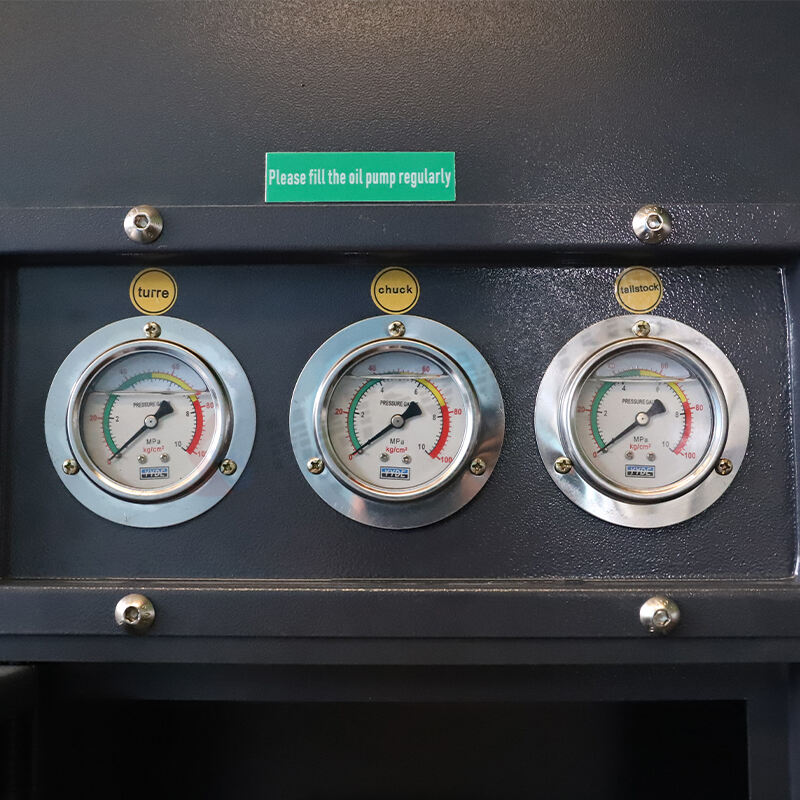

- Details Images

- Packaging & Shipping

- Company Profile

- FAQ:

TCK 56Y series multi-functional CNC lathe is a high-speed precision CNC processing equipment produced by our company. The main accessories are from well-known manufacturers at Home and abroad, and the key parts are completed by the imported precision penttahedral processing center to ensure the manufacturing accuracy.

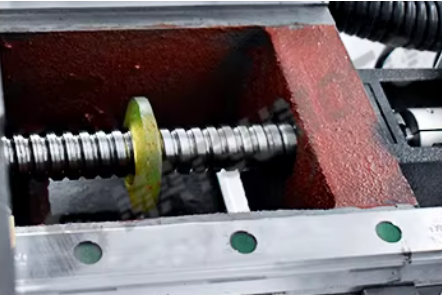

1.TCK 56Y series multi-functional CNC lathe, the bed body adopts box structure and strong cast iron (HT-300), integrated casting technology casting, using high precision machining center once clip processing. Therefore, it has the characteristics of strong overall rigidity, good machine tool accuracy maintenance and high use reliability.

2.The bed body adopts high rigidity 30 (inclined back type integral bed body, convenient to remove chips, with a separation sink, completely eliminate leakage, easy to maintain.

| Specification | Unit | TCK56Y |

| Max.swing over bed | mm | 650mm |

| Max.processing length | mm | 540mm |

| Max cutting diameter | mm | 540mm |

| X-axis travel | mm | 280 |

| Y-axis travel | mm | ±50 |

| Z-axis travel | mm | 750 |

| X-axis movement speed | mm/min | 24000 |

| Z-axis movement speed | mm/min | 24000 |

| X/ Z axis Feed rate | mm/min | 0-5000 |

| X/Z axis manual feed speed | mm/min | 0-1260 |

| X-axis repeatability | mm | 0.005 |

| X-axis positioning accuracy | mm | 0.008 |

| Z-axis repeatability | mm | 0.006 |

| Z-axis positioning accuracy | mm | 0.008 |

| Spindle speed | rpm | 10-3000 |

| Maximum spindle torque | N.m | 72 |

| Spindle nose end | - | A2-6 |

| Spindle through-bore bore diameter | mm | Φ66 |

| Coolant capacity | L | 200 |

| Motor type | kw | 1.1 |

| Machine size | mm | 4300*2100*2400 |

| Weight | kg | 4200 |

|

Standard Configuration: |

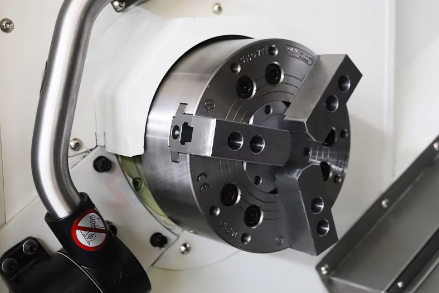

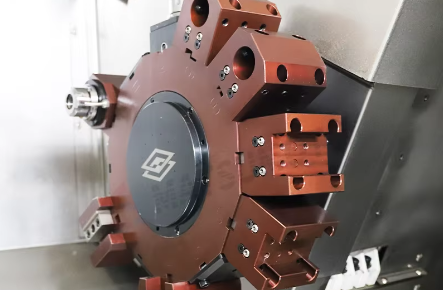

Optional Configuration: 1.CNC System: KND1000Ti, Fanuc Oi Mate-T 2.Main Motor: Servo 11/15 KW 3.Turret: 8 station electric turret 4.Chuck: 8″Non-through hole hydraulic chuck 5.8″Non-through hole hydraulic chuck (Taiwan) 6.8″through hole hydraulic chuck(Taiwan) 7.10″Non-through hole hydraulic chuck 8.10″through hole hydraulic chuck(Taiwan) 9.Chip conveyor 10.Steady Rest 11.Without tailstock 12.Inverter 11 KW |

|

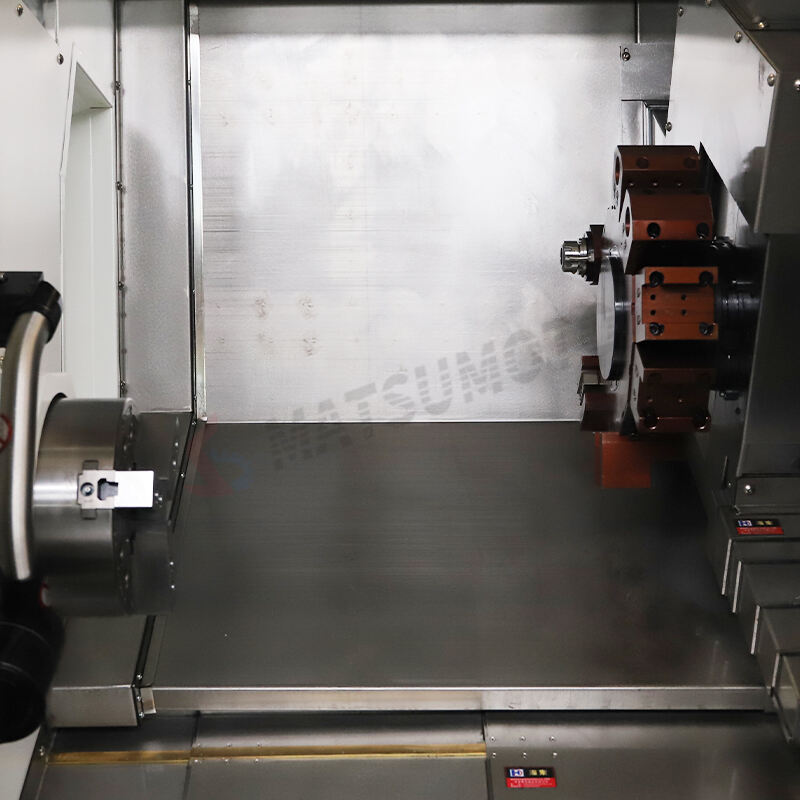

BED CASTING

|

|

|

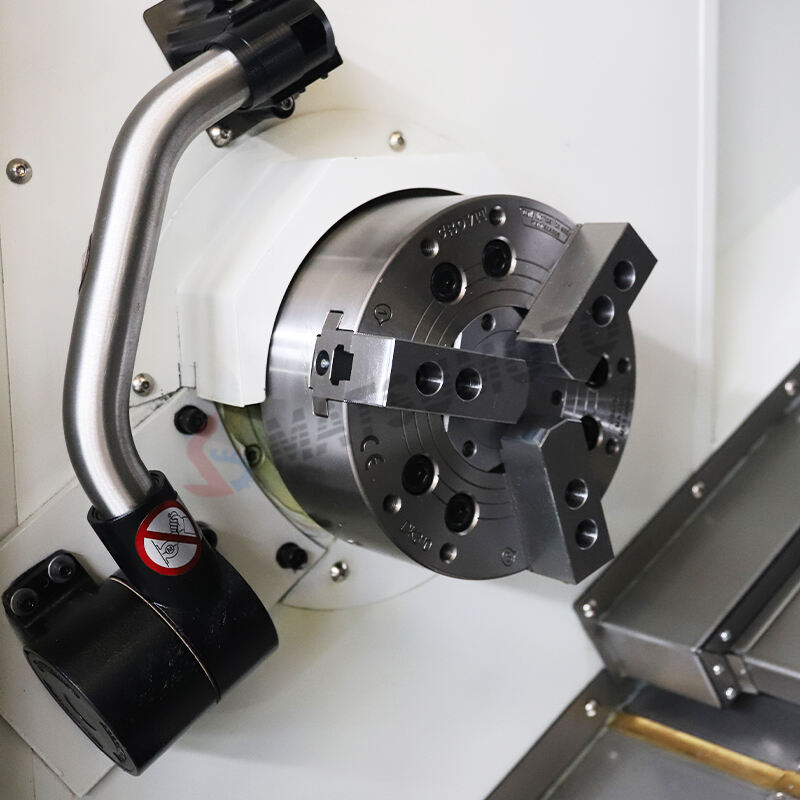

PNEUMATIC CHUCK

|

|

|

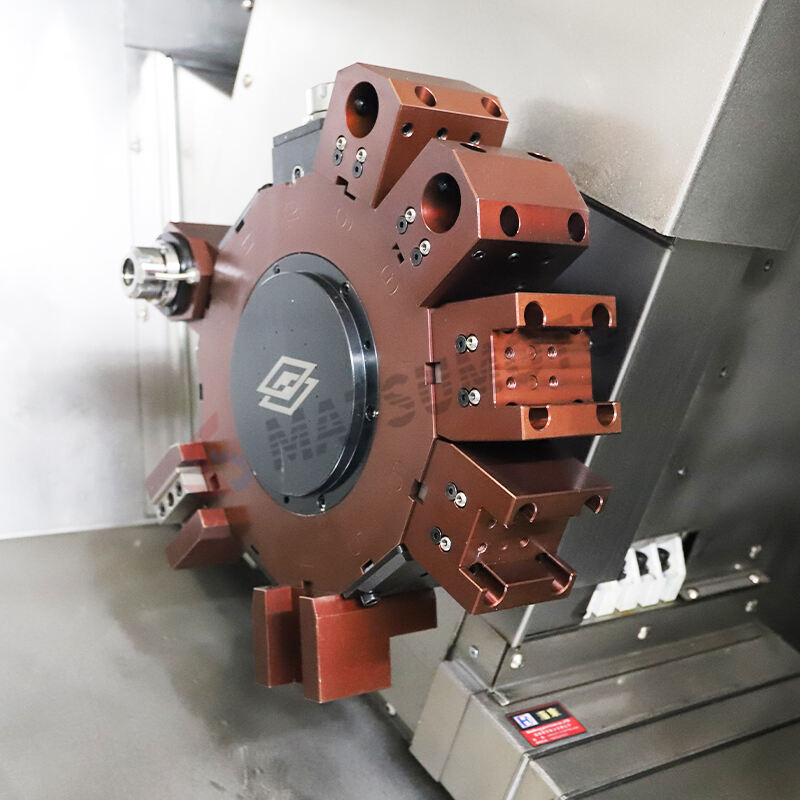

POWER TOOL TOWER

|

|

|

GUIDE

|

|

|

CNC CONTROL SYSTEM

|

|

1.Standard plywood case,its compressive strength and bearing quality is better.

2.The board area is bit,the soil structure is good,it is better in leak proofness and waterproof.

3.When importing,the plywood case is with fumigation-free,the procedure is simple.

4.Delivery Detail:within 7-15 days after received your payment.

Shandong Matsumoto Machine Tool Co., Ltd.specializes in the production of processing machine tools. Its main Products include precision products such as CNC lathes, surface grinders,milling machines, and vertical machining centers. It has a complete and scientific quality management system. Shandong Matsumoto Machine Tool Co., Ltd. operates with integrity, and its production strength and product quality have been recognized and praised by the industry.It is a comprehensive machine tool manufacturing enterprise integrating CNC machine tool manufacturing and consulting services. The company has a complete R&D and after-sales service team. Welcome to visit, guide and negotiate business with the company.

Main products:

CNC LATHE MACHINE、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine.

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine and so on .

3: What about the quality of the machine?and after-sales service?

A : Our machine warranty period is 3 years,and we provide free technical service.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )