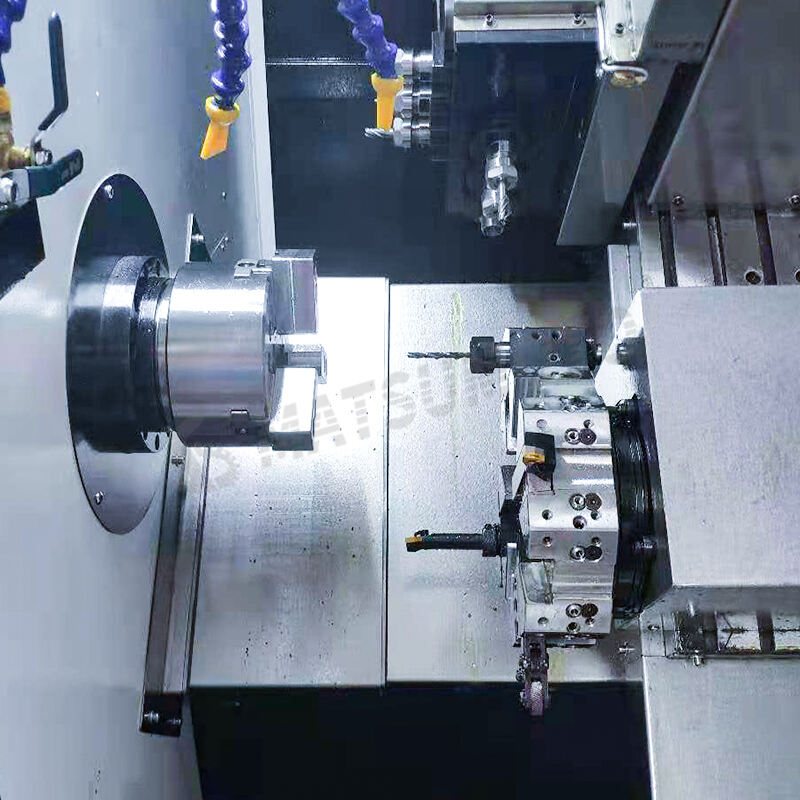

cnc lathe slant bed

The CNC lathe slant bed is a precision machine tool designed with an angled bed for enhanced performance and efficiency in metalworking. Its main functions include rotating a workpiece about an axis to perform various operations such as cutting, knurling, sanding, and facing. Technological features of the slant bed CNC lathe include a robust structure, high precision, and advanced control systems that allow for intricate detailing and repetitive accuracy. The slant bed design facilitates better chip disposal and operator accessibility, which are crucial for continuous production. This machine is widely used in industries such as automotive, aerospace, and general machining for the production of complex parts and components.